Rethink the Rink Make-a-Thon

Making Hockey Safer

Evolving the goalie mask design to be safer and more resilient from puck shots

Role: Product Designer, project manager

Timeline: 1 week

Context: annual student make-a-thon hosted by cmu, the pittsburgh Penguins organization, and covestro

Team: 2 mechanical engineers, 2 chemical engineers, 1 Product Designer [myself]

Impact: Rapidly prototyped goalie mask design over one week to win most innovative prototype award

Former Penguin goalie Marc-Andre Fleury makes the save

The Challenge

Background

Taking puck shots is a normal part of playing ice hockey, and nobody knows this more than the goalie. Unfortunately, blocking these shots can put goalies at risk, at times leading to serious concussions or even traumatic brain injury. NHL players have access to the most state of the art protective equipment, but youth players can’t always afford that luxury. We needed a helmet redesign that was accessible enough to repurpose for all helmet types.

Problem Statement

How might we design a goalie helmet concept that requires minimal modification but can still take those powerful headshots?

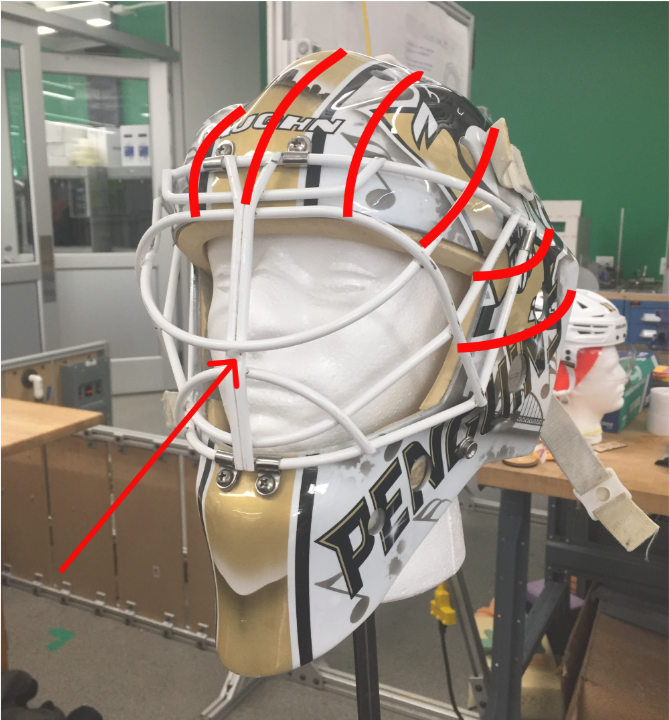

The Solution: DSPONSE — a new dual-response goalie helmet that absorbs puck impact

Over the course of 5 days, students from all engineering disciplines came together to help redesign hockey equipment to make things safer for players. Using expert resources from the Pittsburgh Penguins, Covestro’s material science team, and CMU’s Engineering department, our team developed a prototype for a dual-response goalie helmet that absorbs impact from puck hits and helps prevent head injury.

Our presentation poster

PROCESS

Pain Points

From our interviews with hockey SMEs, including Penguins equipment manager Dana Heinze, and materials experts from Covestro, we identified the following:

Don’t cramp their style — Hockey players are very superstitious about their equipment. As such, they are hesitant to get new equipment until it’s completely fallen apart. They’re also very particular about the look and feel of the helmet, viewing it as an extension of their own personal style.

Watch the head — While goalies can take shots from mostly anywhere, headshots are the most damaging and leave players most rattled. Extra protection is needed on the helmet without being too heavy or obstructive to their field of vision.

Methodology

With our shortened time frame, we sought research from all angles, talking to hockey SMEs from the Penguins organization, hockey players in our networks, materials SMEs from Covestro, and machine shop experts for recommendations for materials and construction. We even got to cut up some old hockey equipment to see how it was made!

Since our team was engineering heavy, I performed some informal literature review and pulled data for average shot speeds to help us calculate what types of forces our mask redesigns would potentially need to withstand.

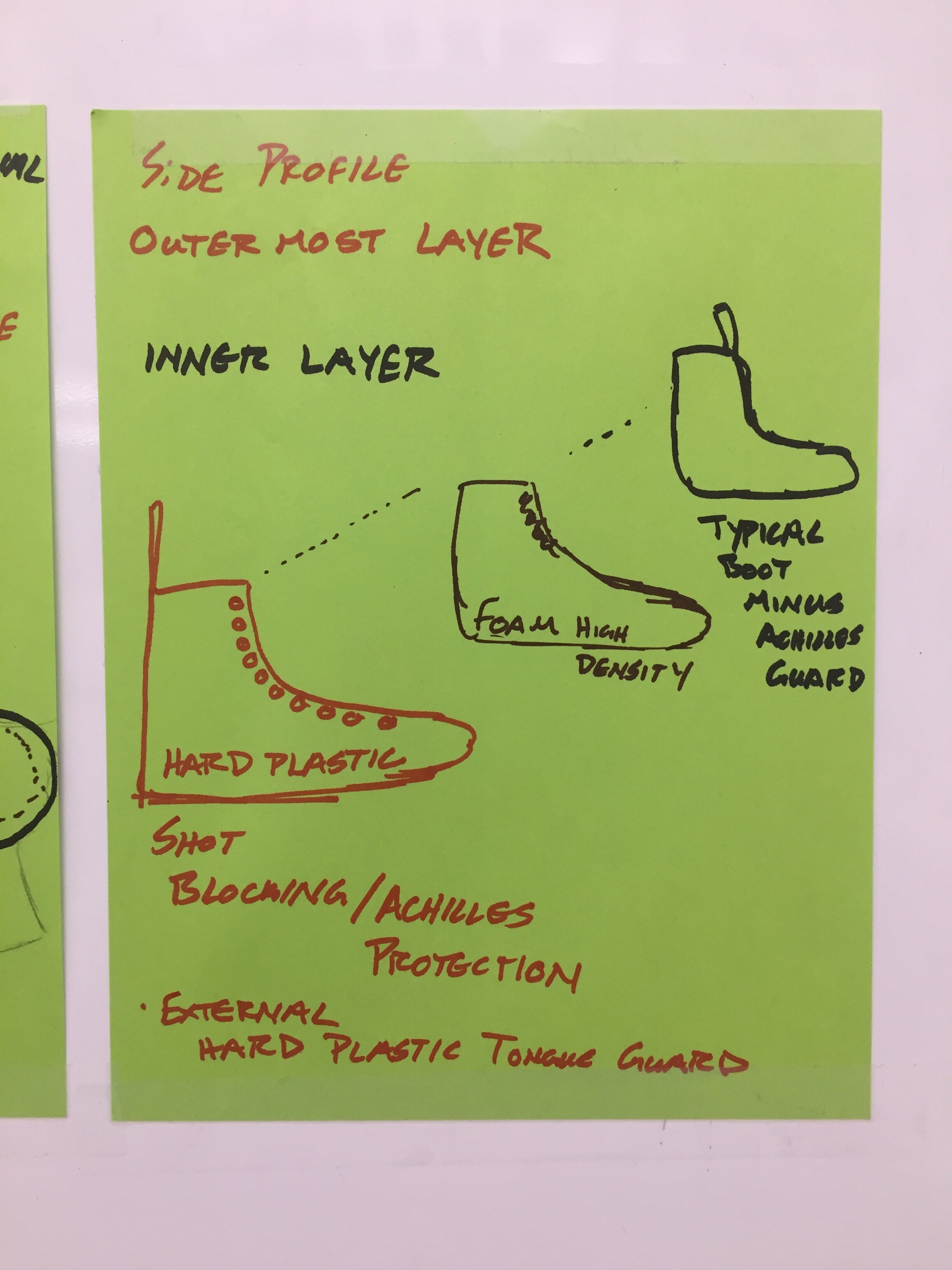

Below: Some shots of our process, including ideation, interviewing, exploration of prototype designs, and trying on goalie masks for fun

END RESULT

Final Design

Functionality

Our mission for our design was to help absorb puck impact before it gets to the player’s head through an innovative dual-response energy absorption approach. Contrary to conventional mask design, the body of our mask is in two parts:

Use of TPU air bladders and spring components to keep the force away from the player’s heads

Note: This tech is similar to what’s used in the bubbles in Nike AirMax shoes!

A fiberglass cage to mitigate the immediate impact from any shot.

Look and Feel

Using this design, players will experience a fraction of the impact directly to their heads without changing the overall look and feel of the mask. In our research, we uncovered that hockey players are extremely attached to the style or look of their particular equipment (be it for comfort or sentimental/superstitious reasons). As such, we wanted to design a solution that improved player safety but still felt the same when wearing it, without impact to player performance.

Impact

After a *very* short week of research and rapid prototyping, our team had the privilege of presenting our final prototypes to representatives from the Penguins organization, Covestro, and Carnegie Mellon’s College of Engineering.

As a fun perk, we got to present our project from center ice of the UPMC Lemieux Sports Complex.

At the end of the day, our team took home the “Most Innovative” design award and had the opportunity to tour the Penguins’ practice facility and locker rooms.

Our team hanging out in the Pens locker room with our award

Reflection

While this project was only a couple days long and not a typical UX project, I learned a ton about design thinking. Here were some of my key takeaways:

Look ma! We’re on TV!

You can approach any problem with a UX mindset — This wasn’t the standard UX/UI design project by any stretch of the imagination. However, I was able to look at this project with a UX mindset, thinking about the key users in play, ideating wide and eventually converging on some solid ideas, and rapidly prototyping.

When in unfamiliar territory, be a sponge — Being the only non-engineer in the room, I quickly had to find ways to be supportive to our project design. In addition to research, I found ways to help with visual design, project management, and more, all the while learning a ton about mechanical and materials engineering.

Your ideas don’t have to be perfect. — In true hackathon spirit, time was absolutely of the essence. We very quickly had to get comfortable with not running complete research or design sprints on our ideas. At the end of the day, imperfection is expected in these environments; just make sure your idea holds water.